Knutsen NYK Carbon Carriers AS (KNCC), a joint venture company between NYK Line and Knutsen Group, and Pace CCS (Pace) has completed a Joint Study to assess CO2 specification of Elevated Pressure (EP) shipping.

Corrosion and dry-ice formation is a major risk faced by many CCS industrial projects. Impurities present in captured CO2 can lead to chemical reactions and other interactions that lead to corrosion/ erosion and also make it challenging to maintain liquid form during storage and transport operations. EP shipping takes place at ambient temperatures which are significantly higher than refrigerated shipping conditions such as Medium Pressure (MP) and Low Pressure (LP) leading to less energy requirement along the CCS value chain.

The study investigated and determined the following items:

1. Corrosion/Erosion

EP shipping provides a greater temperature safety margin than MP and LP from corrosive liquids. EP shipping is significantly less sensitive to corrosion driven by carryover products from the capture process (TEG (Triethylene glycol) or methanol).

KNCC’s LCO2-EP Cargo Tank has design features mitigating and preventing strong acid condensation. Therefore restrictions on impurities such as NOx and SOx may not be required.

The vertical pipe design of LCO2-EP Cargo Tanks both on temporary storage and vessels also allows for full draining of the LCO2 cargo during routine operations, which prevents long residence times of corrosive/erosive elements.

2. Light Ends

CO2 carrying capacity in liquid form is heavily influenced by quantities of light ends (such as hydrogen, nitrogen and methane) contained within the CO2. A typical minimum CO2 specification for EP shipping may be 98% CO2, compared with 99.8% or even more restrictive seen for other shipping modes. This flexibility enables simpler, lower cost capture and liquefaction processing facilities.

3. Energy Efficiency

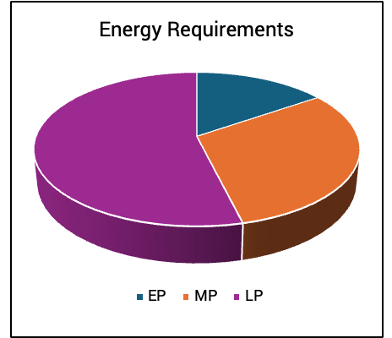

The energy required for liquefying, transport and conditioning for injection were evaluated from post capture for LP, MP and EP. The results show that liquefaction and CO2 handling requirements for EP shipping require up to 50% less energy than MP shipping, and 70% less than LP shipping as CO2 in EP condition has higher enthalpy and much closer to injection conditions.

The following energy requirements were calculated for a typical liquefaction and heating process, as would be needed on an example harbour-to-harbour CCS shipping project: 6 MW/MTPA for EP, 12 MW/MTPA for MP, and 21 MW/MTPA for LP.

Matthew Healey, CEO of Pace CCS said,

“Elevated Pressure CO2 shipping is a no-brainer for many, if not most, CCS projects. EP shipping can offer safer, lower cost, low complexity CO2 shipping operations. The results of this study offer further support to our independent recommendation to consider EP shipping on many CCS projects around the globe.”

Oliver Hagen-Smith, CEO of KNCC said, “CO2 shipping needs to be a major new industry to support Net Zero goals worldwide. We believe that our Elevated Pressure shipping technology will be the global leader, thanks to its inherent simplicity and safety. This Study provides the confidence that EP shipping, generally, may accept CO2 from any capture facility without need for removal of components, being that light ends or those generating adverse chemical reactions.”

Source: KNCC